| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2010-04-25 |

| Manufacturer: | Madcow Rocketry  |

Brief:

Todd:

Mad Cow Rocketry's new Squat is a fun little kit that has been released in conjunction with this year's LDRS theme of "29". As of the writing of this article, they are running a special on it for $29.00. The Squat brings a whole new dimension to the stubby kit. The scale of the kit is very deceiving in photos. The main body tube is 4", but with nothing to compare it to it looks much smaller! I was shocked at how big the kit was when it came in the mail.

Howard:

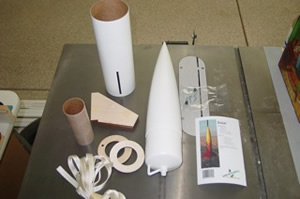

This kit was a bit of a departure for me. I have built a few 4 inch diameter rockets with 54mm motor mounts. They have all been 4-6 feet tall, and most of them dual deployment. This is actually my first stubby high power rocket. I am still impressed with the value you get with this kit. Look at all of the parts included, and consider that this was all for just more than the retail cost of the nose cone. If you need a 4 inch nose cone, buy a Squat kit instead. All of the parts are of excellent quality.

Todd:

I completely agree with Howard on this! Great cost to value ratio on this kit! Nice thick walled body tube with laser cut fin slots. Laser cut plywood fins that are exactly the right size. Enough shock cord for two rockets. A honkin' big very cleanly molded nose cone. The only things not included with the kit are the parachute and the motor retention.

Construction:

Kit contents:

- Nose cone: Absolutely huge

- Body tube: 12 inches by 3.9 inches, preslotted

- Motor mount: 54 mm by 6 1/8 inch, LOC compatible

- Centering rings: 1/4 plywood, 3.9-2.1 for LOC 54mm MMT, one has hole for eyebolt

- Fins: 1/4 plywood, laser cut

- Rec. harness: 11 feet of 1/2 inch tubular nylon (wow)

- Eyebolt and washer and nut

- Rail buttons: 2

- Instructions

Howard:

Howard:

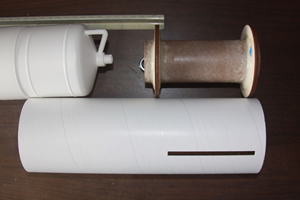

I lined up the motor mount flush with the bottom of the airframe, and the nose cone with its shoulder at the top of the airframe. Look how little space there is between the nose cone and the motor tube.

Can we really fit the parachute and harness in there? I am skeptical. I also anticipate that we will need nose weight to use any 54mm motors. So I had two reasons to want to use the space inside the nose cone.

I took the nose cone over to the miter saw and cut the bottom clean off. Then I roughed up the inside with coarse grit sandpaper to give the epoxy something to grab. A 2 inch bulkhead with an eyebolt is

being epoxied in over the 60g of steel shot I put in the very tip of the nose. These parts are not supplied with the kit.

being epoxied in over the 60g of steel shot I put in the very tip of the nose. These parts are not supplied with the kit.

Todd:

I independently came up with the same solution for my Squat build, but for different reasons. I was concerned about scorching the shock cord and parachute. There just wasn't enough room to get a safe amount of dog barf wadding in along with the recovery components. I wasn't quite as precise, just eyeballing my cut along the rear friction ring of the cone with a hack saw. Also, I didn't know how much weight that I wanted to add when I was building, so I drilled a 1/4 " hole in my plywood bulkhead so that I could add nose weight afterwards.

Howard:

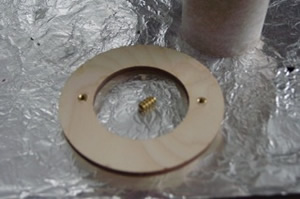

The eyebolt will not go on perpendicular to the centering ring. I also think that if I put it parallel to the circumference of the ring I will not have enough room to get a QuickLink on and off. So I put it at an angle. Just enough to clear the inside of the body tube.

I put these barrel nuts in the aft ring to hold the screws that hold the motor retaining clips. They are tricky to get in perpendicular to the plane of the ring. I actually made them a teensie bit too close to the ring. I had to field-modify my clips to make them fit. I should have measured. (Sigh.)

Here they are showing what they do.

Todd:

For motor retention for my Squat, I installed 6-32 t-nuts. I will be securing the motors in with 6-32 machine bolts and either mirror clips or electrical conduit clips, depending on the motor size. Either the barrel nuts or t-nuts offer a good low cost solution to motor retention. Not quite as pretty as a Aeropack motor retainer, but only a fraction of the cost.

Howard:

Why did I take this picture?

Todd:

Be careful not the get the eye bolt lined up with the fin slots!

Howard:

Howard:

Maybe that was it. No! I was showing how I put epoxy on the eyebolt nut. You are never going to see it again, so it had better never come loose!

I was extremely pleased with how perfectly the fin tabs fit into the laser-cut fin slots. Wow! I aligned each fin by eye. Then poured internal and external fillets.

Todd:

Before gluing my fins into the slots, I hit them with a belt sander to put a bit of an airfoil on them. Rounded on the front, tapered on the back. Howard deviated a bit from the instructions by leaving the rear ring off to be able to add internal fillets. The  instructions do not mention internal fillets. They are not a bad idea, but I decided to not add the extra weight at the rear of the rocket. Without the internal fillets, external ones are not only a good idea to add strength, but also give a much more polished look to the completed rocket.

instructions do not mention internal fillets. They are not a bad idea, but I decided to not add the extra weight at the rear of the rocket. Without the internal fillets, external ones are not only a good idea to add strength, but also give a much more polished look to the completed rocket.

Howard:

Reminds me of an Imperial Shuttle.

Todd:

"Luke... I am your father..."

Howard:

Howard:

After gluing in the aft centering ring I not only filleted it, but I painted the 30 minute epoxy over the whole after surface, including the trailing edges of the fins, to protect it all from heat damage. I managed not to get any inside the barrel nuts. That would have been bad.

Todd:

"Right. Don't cross the streams. Thanks for the important safety tip Egon." Small bits of masking tape over the holes kept epoxy, primer and paint out of my t-nuts throughout the build.

Howard:

Tape. Over. The. Holes. Sometimes I overlook the easy solutions. (Shaking head)

Finishing:

Finishing:

Ready for paint. I didn't bother rounding or airfoiling the fins. It's a stubby rocket. I'm not going to be setting any altitude records with it. The construction was straightforward. No surprises or gotchas. I did not try to follow the directions, though. (I deviated - Thanks, Todd) I think they are a little over simplified. No internal fillets, for example. I believe that cutting the base of the nose cone and adding nose weight were necessary modifications. I don't think you could get any H or I motor in there and make it stable without using that space I will give 4 stars for construction.

Todd:

I agree with Howard. This is about as straight forward a built as it gets. Just watch out not to line up the eye bolt or your motor retention with the fins slots and you can't go wrong. The instructions are adequate even if the builder only has a minimum of high power experience. I also give the Squat 4 stars for solid, straight forward construction. Finishing I varied from my normal finishing routine on the Squat. After sanding down the whole rocket, I hit the tube spirals with Bondo instead of Elmer's Fil'n'Finish. I also thickened up the fillets and touched up a fin that I had slipped and knicked with the belt sander. After sanding again, I coated the rocket body and fins with high build Dupli-color automotive primer. I got a very nice smooth finish with only a single coat. It seemed to clog the sandpaper less than my normal Kilz as well. For the nose, I scuffed it up with 150 grit sand paper and primered it with a different Dupli-color automotive primer that supposedly etched it's way into the surface as it cured. A test patch on the non-scuffed cut off base of the nose did not look good as the primer flaked off easily. Scuffing the surface made a world of difference though! The nose primer sanded nicely after curing over a couple days. Both the nose and rocket received a couple coats of finish color. with wet sanding between coats. I give the Squat 4 stars for finishing.

Howard:

Yikes! Etched into the surface? When you told me that I had visions of the bad guy from the movie Alien.

Finishing, oh yeah. I was definitely a minimalist here. The kit has no decals, and no real recommended paint scheme. Every one I have seen has been different. The picture on the instructions has a nice flame pattern on it. I did nothing so fancy. I sprayed on a couple of coats of white Kilz, with a light sanding after each coat to remove the fuzz and smooth the surface. Then I sprayed it with a couple of coats of gloss black enamel followed by a coat of clear enamel to even out the gloss. I left the nose cone unfinished white, since I knew I didn’t have anything that would stick to it. I think the black and white was fine for a first draft. I am planning on giving it some detail now, but I have not decided what to add. I give it a solid 4 for finishing. Could have been a five, but that nose cone is difficult to paint.

Construction Rating: 4 out of 5

Flight:

First of all, getting the CG right with the I150 did require nose weight. Mine was OK with the 60g I

had in there. Todd had to add some. The first flight for both of us was on the Cesaroni single grain 54mm I150. We did a drag race.

had in there. Todd had to add some. The first flight for both of us was on the Cesaroni single grain 54mm I150. We did a drag race.

Another of our club members joined our race with his own Squat, which he had built with electronics in the nose. Cool. We left the pad before him since he had an Aerotech motor. All three rockets performed perfectly. I hear Todd stuck his landing.

Mine landed on a bush and got a minor scrape on the nose cone. Also, my 9 second delay was a little long. 7 would have been better. Given that I had landing damage, the 30 inch chute may have been small, but it worked fine on the second flight.

Todd:

Wow! What a drag racer the Squat is! The Pro54 1 grain Blue Streak propellant is now one of my favorite motors! I can't wait to try it on VMAX for the LDRS drag race! My flight seemed like it was  just past apogee when it deployed. Probably a second or two late. I did stick the landing on one fin! This was a worst case scenario without the internal fillets, but the Squat took it like a champ, probably due to it's stubby proportions.

just past apogee when it deployed. Probably a second or two late. I did stick the landing on one fin! This was a worst case scenario without the internal fillets, but the Squat took it like a champ, probably due to it's stubby proportions.

Howard:

My second flight was on an Aerotech H242-M. This motor was perfect. It is a 38mm motor, and I used Dr. Rocket 38-54mm adapter closures. Because of the shortness of the motor mount, the adapter closures will only work for 1 or 2 grain 38mm Aerotech motors. With a 3 grain motor the forward closure sticks out of the motor mount, so some other motor adapter method must be used.

Todd:

For my second flight, I wanted to take CTI's new 3G motors out for a test spin and make it 5G! Green flame, green propellant, green rocket, green 'chute. I settled on the 6 grain Pro29 H159. The casing stuck all the way up into the nose cone! I slid the shock cord protector I had added all the way up and packed the rest of the cord and the 'chute down around the motor tube and put a handful of dog barf on top of the laundry. Great flight! I dialed the delay a little shorter and it popped just before apogee.

Howard:

So, between us, we launched it on 29mm, 38mm, and 54mm motors. Pretty versatile little rocket. My

third flight was a little scary. The Cesaroni I120 blew through its ejection charge during the boost, resulting deployment while still under thrust. The rocket did some sky writing, and fluttered down with its chute fluttering on two of its 8 shroud lines. The inside of the airframe is barbecued, but it still seems airworthy.

third flight was a little scary. The Cesaroni I120 blew through its ejection charge during the boost, resulting deployment while still under thrust. The rocket did some sky writing, and fluttered down with its chute fluttering on two of its 8 shroud lines. The inside of the airframe is barbecued, but it still seems airworthy.

Todd:

For my third flight, I launched my Squat in a much more challenging environment, San Diego's Fiesta Island. I dropped the power way down to a Aerotech G76-4 hoping to not have to go swimming to recover one of my new favorite rockets! Despite the light breeze, the Squat boosted perfectly and recovered inside the field.

Howard:

Howard:

The flights were superb. I think the CG issues were predictable. I am going to give it 4 1/2 stars for flight.

Todd:

I absolutely concur. I give the Squat 4-1/2 stars for flight. Very nice, stable flights with a wide variety of motor choices available. According to EMRR's maximum lift off weight calculator, my Squat could fly on as small as a high thrust F motor and with the nose cone base cut off, it could fit a 54mm K motor if you have a tracker and enough guts to use it!

Flight Rating: 4 out of 5

Summary:

Howard:

Overall I will give it 4 1/2 stars. This is one cool little rocket, and a bargain not to be missed. I already got one for my daughter. Maybe I need another one.

Todd:

I give the Squat a final rating of 4 stars. A fun little addition to any fleet. This kit is a bargain with great quality components, but has not included some normal amenities to give you such a deal. Probably not the best kit for a first time high power flier, but would be a great project for someone with a bit of experience.

Howard:

I have to agree. I think that if a novice built it completely unmodified, it might be hard to get the CG right. To Madcow’s credit, the recommended CG location is printed right on the front of the instructions, so nobody who is paying attention will launch an unstable rocket.

Overall Rating: 4 out of 5

|

|

Flights

|

|