| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 0.54 inches |

| Length: | 19.50 inches |

| Manufacturer: | Custom Rockets  |

| Skill Level: | 3 |

| Style: | Futuristic/Exotic |

Brief:

P.O.N.G. is a highly-detailed single-stage futuristic sport model offered by Custom Rockets. This is an inexpensive

kit that packs a lot of fun, challenge, and parts in a small package. This is a skill level 3 rocket that won't

disappoint.

According to the kit label, P.O.N.G. is an acronym (er, backronym, really) for Protector of Ninth Galaxy. There was no background story included with the kit, which is too bad really. The look of the kit is intriguing. I would be pretty cool to have it backed up by a little story.

My finished model weighed 1.2 ounces, but the kit's glossy claims 0.7 ounces. I'm unsure of where the additional weight came from... paint, glue, and sanding sealer?

Construction:

Included with the kit are:

- 1 instruction sheet, tri-fold, 8.5" x 11"

- 1 standard ping pong ball

- 2 body tubes, BT-5, 9" long

- 2 body tubes, BT-50, 1.85" long

- 2 tube couplers, BT-5

- 4 centering rings, fiber, BT-5 to BT-50

- 2 wooden dowels, 1/8" dia., 6" long

- 2 launch lugs, 1/8" dia., 1.5" long

- 1 engine block, 13mm

- 1 shock cord, flat elastic, 1/8" wide, 17" long

- 1 balsa sheet, die cut fins, 1/16" thick

- 1 streamer, pink vinyl, 3cm wide x 60cm long

- 1 dummy engine tube, 13mm

- 1 reducer shroud sheet, printed, light card stock

- 1 decal sheet, pressure-sensitive plastic, not die-cut

- 1 decal sheet for shroud, adhesive-backed paper, not die-cut

Because I no longer have faith in the tri-fold shock cord mount when not protected by a baffle, I added the following items for a Kevlar® and elastic alternative:

- 1 Kevlar® thread, 10" long

- 1 shock cord, round elastic, 1/16" dia., 24" long

- 1 cotton thread, crochet-style, 4" long

The body tubes have a fairly shallow spiral, so they should be easy to fill.

I found that the instructions were easy to follow and that the illustrations were clear and very helpful. The assembly order was logical. To implement the Kevlar®/elastic shock cord, I tied the Kevlar® cord to the engine block just prior to gluing in the engine block.

When gluing in the engine block I ran into a snag. The motor tube got stuck in the body tube, and I pretty much destroyed the dummy engine tube when getting it out with a pair of needle-nose pliers. I must have gotten a bit of glue too close to the end of the body tube prior to inserting the block. Luckily, the main body tube was not damaged.

In general though, assembly was a lot of fun... Far more engaging than piecing together a 3FNC model. Hobby knife skills were important and were well exercised, having to separate the die-cut fins and centering rings, cut the dowels, cut the reducer shroud pieces, cut the shroud decal, and cut the individual decals from the pressure-sensitive decal sheet.

There's so much here that you just don't get with plastic laden kits. The paper reducer needed a bit of patience and skill to curl just right. The use of a separate tab glued to the inside edge of the shroud's adjoining ends made a nice even seam without the uneven layers you get with a one-piece overlap arrangement.

This is the first time I've used hot-glue or a ping pong ball when building a rocket. I ran into a snag as I wasn't satisfied with the alignment of the ball's center seam with the centering ring, and I attempted to move things around where they were still hot... Bad move. The ball distorted badly where the glue in contact with the ball was still hot. I replaced the ball and tried again. I had much better results this time. I had been concerned that the hot glue wouldn't provide a strong enough joint, but this experience eliminated that concern. Hot glue is very effective in this case.

Overall, construction was interesting, fun, and educational. There are many interesting activities involved with building this model that made completion memorable and gratifying.

Finishing:

The instructions don't mention anything about sealing and sanding the exposed balsa. I can understand that, since the

decals cover most of the balsa anyway. The decals come pretty close to the edges of the balsa pieces, so you probably

don't want to round balsa edges. I didn't want any grain to show, so I finished the balsa surfaces with three coats of

sanding sealer, sanding between coats.

I spray painted with model with a couple of coats of last of my old-style Krylon white primer, sanded, and applied a couple of coats of white satin.

One thing the instructions to not address is that in order to get your model to look like the picture included with the kit, you need to paint the lower part of the upper tube orange. Using the kit's picture as a guide, I painted the lower 5" of the upper tube with Krylon pumpkin. Oddly enough, the color matched the orange of the decals perfectly.

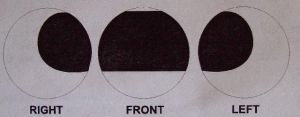

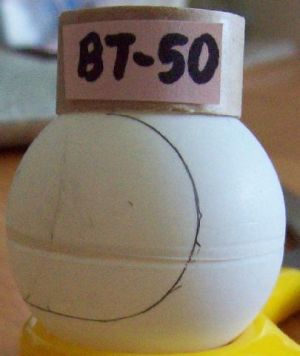

Painting the view plate on the ping pong ball was an interesting challenge. The instructions shows what this should look like. You are instructed to mark the shape with a pencil, but it doesn't tell how to get the shape onto the ball accurately. I used a couple of pieces of body tube to get something close, namely a piece of BT-55 and a piece of BT-50. I've included some pictures to give you a step-by-step.

After marking the ball, I used a superfine Microbrush to apply Testors gloss black enamel inside the lines. I'd never used this technique before. It works very well with a steady hand, patience, and care.

I painted the dowels the same way, slipping masking tape between the body tube and the dowel to allow me to paint the down surfaces facing the tube.

There were many, many decals to place. I tried dipping a decal tube wrap in water to slow down set up time for accurate positioning... Don't do this! It causes the decals not to stick at all. The kit's picture was adequate for figuring out what decals go where.

When all decals are in place, the P.O.N.G. looks very impressive. The balsa surfaces are mostly cover by opaque parts of the decals. The decals applied to the BT-5, unfortunately, tend to lift their edges no matter what I try. I kinda wish these were thinner, more pliable wet transfer decals instead, to avoid this issue.

Construction Rating: 4 out of 5

Flight:

Recommended motors are A3-4T and A10-3T. I tried them both.

P.O.N.G. requires some wadding to prevent the vinyl stream from melting. I used some cellulose insulation to good effect. I spread some talcum powder on the streamer to prevent it from sticking to itself. It was tricky rolling the 24" streamer tight enough to fit into the BT-5 tube so that it would slide out easily. I might cut the streamer down a bit in future to address this issue.

There is no motor retention in this design, so motors have to be friction fit by wrapping bits of masking tape around the motor to make a snug fit. I need get better at this as the motor ejected itself during each of the three test flights.

I used an A3-4T for the first flight, as recommended in the instructions. Boost and coast was very straight and of moderate height with no noticeable spin. It definitely flies like a long rocket, smooth and without wobble. P.O.N.G. arced past apogee and with nose down, deployed the streamer perfectly. P.O.N.G. landed gently in the grass field. Upon recovery, I noticed that the motor must have been kicked out at deployment.

I used an A10-3T for the second flight. Boost was noticeably faster. Coast was again very straight, but the height was noticeably lower. I suspect the drag of the nose and abrupt transitions becomes more critical with the speed burst of the A10-3T. The slower, gentler A3-4T is a better match. P.O.N.G. arced past apogee and deployed the streamer with nose down. Another gentle recovery, and the motor had been kicked out again.

I used a A3-4T for the third flight. I got to a nice moderate height after smooth, straight boost and coast. Deployment happened with nose down, but the streamer didn't come out. P.O.N.G. landed in the grass without damage. I found that the cellulose wadding had jammed up in the tube. The motor kicked out before the streamer could deploy.

Recovery:

The standard P.O.N.G. is kitted with a 24" elastic and a couple of tri-fold shock cord mounts. I did not use

these, favoring a Kevlar®

cord with a round elastic. The Kevlar®

cord and elastic were very easy to install during construction, and seemed to work well in flight.

After three flights, the streamer is undamaged. When the streamer deployed, it seemed to do an effective job of slowing descent and being seen during descent and on the ground. P.O.N.G. survived three flights with no damage.

Having to rely on friction fit motors not being kicked out is an issue. I guess I've got to figure out how best to tape the motors in there. Some sort of motor retention device would be a welcome addition.

Flight Rating: 4 out of 5

Summary:

P.O.N.G. is a fun rocket to build, finish, and fly. This is a skill level 3 kit. I agree with that due to the number

of parts, variety of construction activities, and finishing details. It's a nice looking, attention getting model when

its all built, and it flies very well. And when you look at the price tag, wow! Big bang for the buck!

The design and instructions are very good, but I would suggest adding positive motor retention and a mention in the instructions about painting the orange section of the upper body tube and how to accurate draw the view plate pattern onto the ping pong ball.

Overall Rating: 4 out of 5

|

|

Flights

|

|

J.C.B. (December 9, 2009)

Kirk Greenfield (October 29, 2013)

Have run into a snag during construction. The two (BT-50) connection tubes 3/4" long are not identical. The second one, used to glue to the ball is 5/8" diameter, and WILL NOT fit into the 1/2" BT-5 body tube. This appears to be a packing error. The www.customrockets.com website is down, domain available. Not sure how to solve this. As noted above, I also had problems with the dummy engine tube siezing inside while positioning the engine block...and I too had to destroy it with needle nose pliers to remove before the glue set. Had I NOT ruined it, I could have used it as a replacement connector. But it's gone. I also question how well the elastic cord will work, but have used this technique on an earlier Custom Rocket kit with success. I also noted no instruction to seal and sand some of the fins. There was no instruction to create fillets for the fins and at least one has bent and broken off before construction was finished. Will take Dwayne's suggestions on painting. I have not tried the decals yet.

Roger Smith (November 15, 2013)

Custom Rocket's web site is located at http://www.customrocketcompany.com/. You can contact them at sales@customrocketcompany.com.

|

|

A.H. (July 15, 2009)