| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Qmodeling  |

Brief:

This is a 2x upscale (OK, 1.96 to be exact) of the original 1970s edition of

the Estes Bullpup, with highly engineered features and upgrades. I've been

avoiding a few of the relatively pricey QModeling upscales lately, but the boat

tail on this sucked me in and I found this a real pleasure to build and fly.

Construction:

You might be a bit surprised when your $73 box arrives. This kit packs into a

very small bag. Once you open it up and start holding the parts though, and

especially when you start reading through the instructions, you'll recognize

this is still a reasonable value.

Parts list includes:

- Plastic molded nose cone/disk+ screw eye anchor

- 2 BT-80 body tubes white glassine

- TC-80 coupler

- Laser-cut balsa fins (2 sets of 4)

- 24mm foil-lined motor tube

- 50/80 centering rings

- Motor mount brace/frame assembly

- E-sized metal clip

- Cardstock boat tail assembly

- 30" Top-Flite nylon chute

- Nomex® heat shield

- Kevlar® shock cord

- Waterslide decals

Parts are excellent quality, and despite very tight packing arrived undamaged. The instructions for this are first rate, come loaded with construction tips and techniques, and contain plenty of detailed computer-rendered drawings. Of particular note is a recent change by QModeling to include a high-quality color cover page on their instructions, with the back side of that page now being used for finished color illustrations for the paint and decal scheme. That enables them to present great quality, in color, and only have to blow the money on one sheet, printing the rest of the instructions on standard laser printed paper.

By now you've

probably seen at least one other QModeling review and understand their

sometimes over-the-top engineering of construction details like their motor

mount assembly, which typically includes about an 8-12 piece assembly of braces

and support rings. When I heard they had "designed" the boat tail on

this, I couldn't wait to see what these guys had come up with. Right off the

bat, step one of the project begins with the construction of the boat tail.

By now you've

probably seen at least one other QModeling review and understand their

sometimes over-the-top engineering of construction details like their motor

mount assembly, which typically includes about an 8-12 piece assembly of braces

and support rings. When I heard they had "designed" the boat tail on

this, I couldn't wait to see what these guys had come up with. Right off the

bat, step one of the project begins with the construction of the boat tail.

A typical boat tail on a kit like this might be a paper shroud pattern, rolled, glued, then supported on each end by a cardboard centering ring. Maybe you paint it with a thin application of CA to stiffen it. It's not so simple with these guys...

The shroud is straightforward, albeit made from heavy cardstock. They save you the hassle of cutting by providing a laser-cut shroud. There's also a separate laser-cut tab, to avoid the unsightly seam caused by the standard overlap tab included on a shroud pattern. Once you've rolled the cone and tacked it in place over the tab, let it sit for a good hour or so (and pin it with paper clips). It's especially important here, as they note in the instructions, is the use of white glue (no shrink) instead of yellow/wood glue.

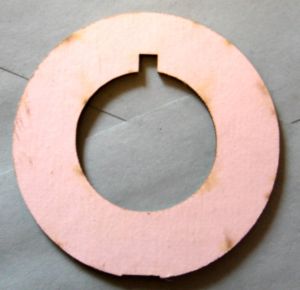

Next up is

bonding the 4 centering ring supports inside the cone. Now, realizing that the

tab avoided the seam on the outside of the cone, but still leaves one on

the inside that could be pushed out into a visible bump with a tight centering

ring fit, QModeling actually laser cut the centering rings with slight notches

to accommodate the tab. Each was precisely engineered to fit at very specific

locations within the cone, offering support at the aft and forward ends plus

the center. I was shocked to find my centering rings actually a hair undersized

and had to compensate with a layer of paper wrapped around the outer diameter

on 3 of the 4 rings. After roughly 2 hours (actually about 30 minutes of hands

on work), I was looking at a nearly flawless boat tail. I finished it off with

a light application of Elmers Wood Filler sanded down to hide the barely

noticeable glue seam on the shroud.

Next up is

bonding the 4 centering ring supports inside the cone. Now, realizing that the

tab avoided the seam on the outside of the cone, but still leaves one on

the inside that could be pushed out into a visible bump with a tight centering

ring fit, QModeling actually laser cut the centering rings with slight notches

to accommodate the tab. Each was precisely engineered to fit at very specific

locations within the cone, offering support at the aft and forward ends plus

the center. I was shocked to find my centering rings actually a hair undersized

and had to compensate with a layer of paper wrapped around the outer diameter

on 3 of the 4 rings. After roughly 2 hours (actually about 30 minutes of hands

on work), I was looking at a nearly flawless boat tail. I finished it off with

a light application of Elmers Wood Filler sanded down to hide the barely

noticeable glue seam on the shroud.

The rest of construction is pretty much standard for QModeling, and I'd direct you to any other review for more details. The motor mount is a very nice foil-lined 24mm tube with a very complicated looking (but easy to build) brace assembly to lock in the through-the-wall fins and a couple of centering rings that fit perfectly in the BT-80 without any sanding. The 200# Kevlar® shock cord is anchored to the forward centering ring.

The aft end of the BT-80 gets a centering ring flush mounted to it. This serves as the base to which the boat tail with a flush mounted centering ring on its forward end is bonded to. While my shroud diameter was almost perfect, there was still a noticeable seam where the shroud and BT-80 join mainly due to the angled shroud edge against the tube. However, another more liberal dose of wood filler was applied and that problem was resolved.

With all the effort to design a seamless boat tail, I'm still amazed and a bit disappointed that this, like the Viper, has a two-piece body instead of a single tube. I suspect this is due to standardization of parts and enables smaller shipping cartons, but I was still dealing with a coupler and a big seam to deal with. For this particular design though, there's a decal over the seam line so as long as you at least smooth it out with decent sanding, it won't show.

I was pleased to see a step in the instructions to fill the tube spirals before bonding the fins. If you want a beautiful finish, this is the way to get it. It's certainly a lot easier to do without the fins in the way. Plus, by sanding down the filler you wind up removing the glossy layer of the tube, leaving a better bonding surface for fins.

The aft fins are through-the-wall and are bonded with wood glue and light fillets. Forward fins are surface mounted and must be lined up by extending lines from the aft fins. I would really have preferred a wraparound guide for marking them, as it's hard to line up the forward fins perfectly by extending lines up from already mounted aft fins.

Having seen me lose 4 tubes to nasty zippers, QModeling now includes zipper reduction/prevention tips in the instructions, suggesting lining the inside of the body tube an inch or so in from the forward end with CA. Good idea, but I also wrap a few layers of masking tape around the Kevlar® where it comes out the tube to soften the cutting strength of it...

Construction finishes up with the nose cone, consisting of a wood disk bonded to the inside lip of the cone shoulder and a screw eye anchor.

There's a closing note referencing the designed CG, which is a very nice touch in this class of rocket.

Finishing:

Other than the hours spent covering up tube spirals, balsa grains and seams,

finishing this is a snap. It's got a plain white color scheme (although the

shadows on their color models make the boat tail look gray). I went with two

light coats of PlastiKote primer, sanded mostly off between coats. I then

followed up with 3 coats of Rustoleum glossy white. I tend to shoot lots of

very thin coats and get a mirror smooth finish.

The decals on this are waterslide but are solid ink, which means before letting them touch water, they need a protective coat of something like Krylon clear coat. I botched up similar decals on my Viper, going too heavy with the Krylon. For the Bullpup, I think the decal ink actually started to run as I pulled the spray can from my closet--I barely touched them with clear coat and my lettering was slightly blurred. These are excellent quality decals, but I've had trouble working with them and suspect they take quite a bit of getting used to.

As noted, the header sheet includes decal placement notes, very specific dimensions and are generally very clear although the 4 views aren't 90-degree rotations, so you don't get a complete view of all decals for placement. I also found two decals didn't quite match the illustration.

Construction Rating: 4 out of 5

Flight:

Given my recent run of bum luck zippering maiden flights (and even a subsequent

flight or two) on the Viper and Nike-X by Q-Modeling, I was a bit nervous with

the Bullpup. I skipped the higher risk (and delay variability) of the E/F

composites, electing instead to go with the Estes E9-4.

The flight was beautiful with a long and slow ascent, not a trace of spin, and ejection was just a hair early as it was just starting to arc over. While I'm sure this would love to fly on an F or at least a full E, the E9-4 is a very nice motor for this. In fact, I am confident it could even go for smaller field flights on a D12.

Recovery:

The 30" nylon chute is a bit oversized for this and it hung in a thermal

for the first 10 seconds or so of the descent, so I had a decent walk for

recovery. I seemed to have cleared all my bad luck as this was free of any

zippering and didn't even show any signs of smoke on the finish.

Flight Rating: 5 out of 5

Summary:

This is an outstanding rocket and a wonderful flyer. If I had to change

anything, it would be getting rid of the two-piece body design and maybe drop

down to a 24-27" chute.

The pros on this would be boat tail design/engineering, great recovery system, and that the finished rocket is light enough to fly on the E9.

Cons are hard to find on this, so I'll nitpick and say I miss their retractable motor hook used on other kits. This one needs a special stand to display or it must lie on its side as the hook prevents standing on the tail.

Overall Rating: 5 out of 5

|

|

Flights

|

|

|

|

J.F.B. (October 27, 2008)