Estes Explorer Aquarius

Estes - Explorer Aquarius {Kit} (2016, 7253) [1989-1994,2018-]

Contributed by John Lee

| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2010-08-17 |

| Diameter: | 2.75 inches |

| Length: | 21.80 inches |

| Manufacturer: | Estes  |

| Skill Level: | 4 |

| Style: | Futuristic/Exotic |

Brief:

Futuristic, Sci Fi, Transport, Parachute Recovery, 24mm motor mount.

The Explorer Aquarius is to my mind one of the nicest looking rockets to have come from Estes. Something about the design says to me, "this could really happen".

I scored mine from eBay and was too intimidated to start it for a long time. Now the time has come and I opened it up. It looks to be much easier than I thought it would be.

Construction:

Construction began by locating the 24mm motor tube and marking off the distance for the engine hook and the centering rings. I thought about leaving out the hook in order to accommodate long E's but decided I would likely use AT E's instead. A slit was made for the hook and the hook was inserted. The instructions said nothing bout wrapping it but I went ahead and added some electrical tape.

The centering rings were then sanded a bit on their inner surface, slipped onto the motor tube up to the marks and glued into place with yellow glue. Fillets were applied to both sides of the rings. I found no thrust ring in the package and found no mention of one in the instructions but figured the rocket would last longer with one so I cut the end off an old E9-6 casing and glued it into place over the engine hook.

At first glance, I thought that I would have to cut the fins from sheet material using a provided template. Not being able to find such a template I took a closer look at the instructions and, sure enough, it mentioned die cut fins. I took a closer look at my balsa sheet and found that it should have been die cut but the impression was so faint that I really had to search for it. The fins were sanded loose and then stacked and sanded to even them up.

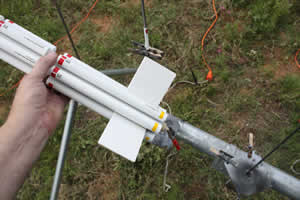

The next step in the instructions was to start assembling all those tanks that give this rocket such a distinctive appearance. There are 6 long tanks and 12 shorter ones. All are assembled the same way. Cardboard end caps are removed from the die cut stock and glued onto the ends of the tank tubes. I used white glue for this. When the long tanks were done, I got started on the shorter ones. After 2 sessions, I finally finished the tanks.

The kit assumes the use of a tri-fold shock cord mount, something I detest. Since the next step involved inserting the motor mount, I went ahead and tied a length of Kevlar® around the motor tube just abaft of the forward centering ring and added a yellow glue fillet. When the fillet had dried, I cut a notch in the centering ring to accommodate the Kevlar® and then fished the Kevlar® through the motor tube to keep it out of the way for the time being.

I used a long swab and white glue and put a ring around the inside of the aft end of the body tube. I then pushed the motor mount part of the way in and applied a second ring of glue just inside the tail end. The mount was pushed the rest of the way in. I was supposed to be flush with the end of the body tube but I left about 1/4" hanging out the back.

A wrap around alignment guide was cut from the instruction sheet and taped into place on the body tube with one of the fin marks aligned with the motor hook. A pencil was then used to transfer the various lines to the tube, the guide removed and the lines extended with an Estes angle. A tapestry needle was then used to make a series of perforations in the body tube where the fin would sit in an attempt to let the glue from some "rivets" and strengthen the joint.

I began to apply the fins using yellow glue and a double glue joint. I added them one at a time, letting them dry thoroughly before rotating and applying the next one. Over the course of a few days, all three were applied. After letting all three dry, I filleted each joint with Titebond Molding and Trim glue.

The fillets got almost a week to dry before I had a chance to work on this rocket again. When I did, I applied Elmer's filler to the balsa because filling and sanding would be easier at this point than later.

The filler had a day to dry and then was sanded down. I took this opportunity to also smooth the edges of the fins as well.

The lines for the tanks had earlier been marked with a pencil and extended the length of the BT. A line was also run the length of the tanks and the end caps of the tanks were marked along with the back edge of the main body tube. This was to aid in alignment as the tanks were mounted. Both the tanks and the BT were also perforated along the lines with a tapestry needle to promote the formation of glue rivets. White glue was then used with a double glue joint to mount the first tank. When it was in place, the tick marks on the end caps were used to line up with the line on the BT.

The aquarius languished for a long while with just 2 of the long tanks in place until I got some free time after Christmas services. I then put in a concerted effort to get the tanks cranked out. All of the long ones were put in place in the wee hours of Christmas morning. I wasn't scared of frightening off Santa because my wife assured me that I had been very bad.

According to the instructions, the next ring of tanks was supposed to be mounted 3/4" in front of the long ones so I marked each of the lines, perforated the BT and tank tubes and applied some white glue for the double joint. When that was dry, I began to apply to apply the tanks with just a trace more glue. I managed to get them to line up pretty well.

It was the last set of tanks where I noticed some trouble. The instructions indicated a gap of 3/4" between each set but that would have left the front tanks hanging out ahead of the body. I went back and checked the spacing I had already done and it worked out correctly but there still was not room for a 3/4" gap. At this point, though I was committed and settled for setting the front row flush with the front of the body tube. The effect is not awful but I would have preferred equidistant spacing.

The nosecone of the Aquarius comes connected to a plastic nozzle intended for display purposes and has to be separated. This was done with an X-Acto saw. The Kevlar® was then fished back through the body tube and instead of using the provided rubber band, I tied on a length of sewing elastic. This was then tied to the nose cone. This let me put things in place and see a preview of what was to come. It wasn't too bad.

The Aquarius almost went to paint when I realized that it did not have a launch lug. I dug through the box and found the 3/16" lug. The instructions said to cut it in half so that is what I did. The lugs were then glued to two tanks in line, one on the bottom tank and one on the top. A piece of rod was used to maintain alignment.

With that, assembly was done and it was time to start finishing.

Finishing:

I normally "prime" my rockets with Kilz, although that is not a true primer. I

decided to use a real primer for this one because Kilz tends to leave a rough surface that needs sanding and sanding

the complex geometry of this rocket would have taken this project from "fun" to "WORK". I decided

to use Dupli-Color white primer. As such, I set it up in the booth and started spraying.

After the priming, the rocket got 2 coats of gloss white.

Masking for the canopy was one of my concerns right from the beginning. Based on some advice from TRF, I ordered some liquid masking film and decided to give that a try. The instructions recommended spraying that on but I have not the equipment for that and a brush it would have to be. After mixing it well, I began to brush it on thick, as per the instructions. The instructions also recommend 2 coats so a few hours later, a second was applied. The film is supposed to be trimmed back using a razor knife to reveal that part where paint is desired. Unfortunately at this step my laziness got the better of me. My X-acto blades were at my shop and I was too lazy to go and get them. That meant that the blade I did the trimming with was too dull. As a result, some of the masking that was desired to remain in place began to lift. The fix for this was simple. I just slathered on some more of the masking film.

A day later, the stuff was dry and I used a new X-Acto blade to reveal the dome. I then used some masking tape and foil to conceal the rest of the upper body and prepare the rocket for spraying.

I was going to paint the dome either a very dark blue or a gloss black but as I was looking through my paints in stock, my eye was caught by a metallic purple. I had bought it a couple of years ago because I REALLY liked the color on the cap. I have used it on several projects but it has never come out looking quite right. I understand the reasons on some of my earlier efforts now and this time I was spraying over white and not some other color. I HAD to try it again because I still really like the color on the lid.

I built the color up in light coats, letting each one dry before applying the next. I put a total of 4 coats on and each one looked deeper and richer than the one before but it never got to where I wanted it. I stopped because I had finally used up the last of the paint, which may have been one of my original purchases when I got back into rocketry.

The paint got a day to dry and then I had a shocking revelation. I had long thought that in the world of rocketry, it was gliders that were my nemesis. This project reminded me that the real bugabear is masking. It does not matter what method I use, the paint always seeps. When I removed the masking and the film I saw that I had failed with the tape, failed with the foil and failed with the liquid film.

To retrieve the situation, I started by sanding down the purple splotches. This did not remove the color all the way but would make covering it with white much easier and remove some of the unwanted texture. I then masked off the canopy area with tape. The capsule then got sprayed with the same white I had used before, receiving 2 coats.

When I peeled back the tape, it looked much better than before. It was not as I had originally hoped but I could live with it. It was ready for decals.

The decals really help to make this kit. I used the original set from the kit which meant that they were fairly brittle. I should have known better but I did not do anything to strengthen them. The instructions for the kit give the decal placements with two illustrations, neither of which is particularly clear. I wound up using the instructions and the photos on the box to aid in placement. The order in which I placed the decals was based primarily on what was easiest to access as I cut them out. I started with one of the smaller solar panels. It cracked in the upper right corner. I almost had it positioned so the the lines matched up when the decal decided to bite and refused to move any more.

Next up came the US flag on the same fin that received the solar panel. From there, I applied the 2 "United States Star Probe" decals on the forward most of the dorsal tanks. After that, I went ahead and applied the large solar panels on either side of the dorsal fin. I used a piece of the decal backing to poke the bottom down between the tubes.

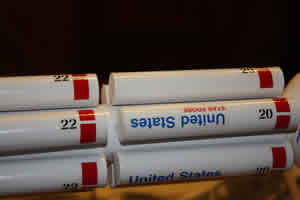

Each of the tanks on the rocket gets a decal of a red stripe and a number. All of the top level of tanks are numbered "29". The middle level are marked "22" and the bottom "25". For some reason, I place one of the top row and did not do any others for a while. Inexplicably, I then turned the model around and finished putting the solar panels on the other sides of the fins and added the other US flag. After that was done, I finished applying the tank numbers to the top level. The only place I ran into any trouble is on the tank with the lug on it. I don't know where I went wrong in the lug placement but I had obviously put it right where a decal was needed. I placed it as best I could.

In order to keep from handling all of the freshly placed decals at the front end of the rocket, I next cut out and applied the yellow numbers "17" along side the flags on the tail fins. Each side of the capsule got an "Aero Dynamics" logo. The back of the capsule then got a decal representing hatch work, etc.

At this point I took a break overnight and let the stuff that had been applied set up. When I got back to it the next night, I added the numbers on the middle row of tanks and then to the bottom row. The aft end of the bottom row also got a series of broad yellow stripes. The middle row of tanks also got some decals identifying them as the center section. After that it was just a matter of a few small detail decals that mostly went on fine. The exceptions to the "fine" part were the last three. They were 3 blue trapezoids to be applied to the bottom of the capsule. Each one cracked and each one gripped before the damage could be rectified.

That completed the building and finishing of the Explorer Aquarius. All that was left was to fly the thing.

Construction Rating: 3 out of 5

Flight:

It seemed like I was out of luck on flying this one. My regular club launch got rained out and

then the make up launch got rained out. I pinned my hopes on an Amateur Rocketeers of Texas Freedom launch but then it

got canceled the day before the big event when the club lost the field. Some last minute arrangements were made,

though, and my regular club had a SNAP launch and the Aquarius was the first of my rockets to get tried.

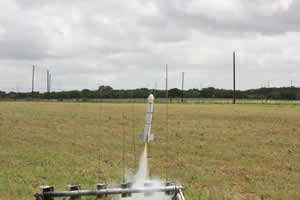

I started small with a C11-3. The day had started out calm but suddenly got windy while we were talking instead of launching and I didn't want to walk too far. I loaded a 15" nylon chute and took it to the pad. Some did not remember this as a classic and thought it was a cool new design.

Ignition was instantaneous and the rocket lifted off nicely. It was going fast enough to be stable but it was slow enough to appreciate as it climbed. It coasted a bit and started to slow. For the first time ever, I was able to capture the actual ejection event. The chute deployed and it looked like it was going to be a perfect, albeit not very high, flight. To make things better, the wind seemed to have died just as it boosted and it was going to land pretty close. When I walked over to get the rocket, everything seemed fine as it lay on the ground. When I picked it up, though, it seemed as if one of the fins was less straight than I had remembered. When I wiggled it, I found that it had popped loose in spite of the glue rivets. This one would need a repair before I could fly it again.

When I got a chance to take a better look at the fin in the shop, I was glad to see that the damage was not too substantial. It basically amounted to the glue and fillet coming up for part of the length of the fin. I did some scraping between the fin and the BT to roughen things up and provide for better glue adhesion. The fin was then pushed back into place to check for fit. White glue was then applied along the root edge and the fin was pressed into place for good. In order to keep things straight and in place as the glue dried, a ring of masking tapes was applied.

It then took quite a while before the Aquarius got back into the field. At my club's May launch, though, it had its chance. I loaded it with a D12-3 and set it out on the rod. As I was getting ready to launch, though, something looked screwy. The rocket was canted. I went out to the rack to take a closer look. It was soon apparent that the lower lug had broken free. I did not have any CA handy but another guy at the launch did (Thanks Ken!) and a quick repair was effected. After the hasty repair, the Aquarius was taken back out to the rack and hooked up again.

Liftoff on the D12 was nice. It was not slow but neither was it a head jerker. The boost was fairly straight. It turned slightly into the wind but not a great deal into the wind. The rocket coasted fairly well too, although not for very long since a 3 second delay had been installed. The chute deployed but did not seem to come all the way out for a few moments, leading me to worry that it had been hung up. Then the chute seemed to open up all the way and it was only a matter of waiting for the rocket to drift on down. I am happy to report that there was no damage.

Flight Rating: 4 out of 5

Summary:

I like this rocket. I think its a shame that it is OOP since it is distinctive and different

from so many out there. I will gladly have it included in my fleet for, hopefully, a long time to come.

Overall Rating: 4 out of 5

Other:

Persons wishing to see the liftoff of this rocket on the D12 are invited to check out this

video: http://www.flickr.com/photos/23694991@N03/4903280722/ Thanks to Glen Larsen

Other Reviews

- Estes Explorer Aquarius By Les Bradshaw

This is an OOP "Sci Fi" rocket that can still sometimes be found. It consists of a main body tube surrounded by 18 "storage pods". It has an unusual plastic nose cone. Estes defines it as "Galaxy Class craft used in exploration of distant star systems". Estes indicated that it is skill level 4. The rocket consists of a main body tube with three sets of 6 tubes attached around the main tube to ...

|

|

Flights

|

|