| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Sunward Aerospace  |

Brief:

Futuristic, military interceptor styled rocket with an 18mm mount and rated for

B6-2, C6-3, and C6-5 motors.

Construction:

This kit is manufactured by a Canadian company and is a little different than

most of the kits that I've become familiar with. The motor hook is a complete

departure from the long thin spring steel hooks we've been using for over

thirty years, there are some marked differences in fin attachment points, and

they have returned to the rubber shock cord of the past.

The parts all come in the standard clear plastic bag, and the overall quality of the parts is very good. The chute material is heavier than most. The balsa is laser cut, medium hardness, and has the correct grain type for the purpose of making fins. The shock cord is an adequate length. The decals are stick on type in two colors (red and white). There is also a large printed cardstock sheet to create various paper construction parts and a shroud that forms the engine nacelles. The instructions are clear and well written in both French and English, and the illustrations are very helpful and well drawn.

Construction begins with the motor mount. A motor block is glued in flush with one end of the motor mount tube and the two centering rings are positioned 5mm from each end of the mount. The motor hook is installed in the ring opposite the block and a motor is test fit in the mount. The Sunward hook is a heavy metal rod with a 90 degree bend at one end and wood screw threads at the other. A pilot hole is drilled in the aft centering ring, which are the wound paper type, and the hook is screwed into the ring. After the motor is installed, the hook is twisted around until it is retaining the motor. After the flight, the hook is twisted out of the way to make removal of the motor possible. The instructions warn that the hook may be very hot for several minutes after a flight.

Fins are next.

Sunward uses a very different approach to fin attachment than most other

manufacturers, too. The typical kit attaches fins directly to the rocket in a

butt joint arrangement and adds glue fillets to the joint. Larger rockets cut

slots in the body tube with the fins passing through the slot and glued to the

motor tube with fillets at the airframe/fin joint. Sunward instead supplies

card stock cutouts that are glued to the sides of the fins at the root edge and

these assemblies are then joined to the airframe tube creating a pre-assembled

fillet.

Fins are next.

Sunward uses a very different approach to fin attachment than most other

manufacturers, too. The typical kit attaches fins directly to the rocket in a

butt joint arrangement and adds glue fillets to the joint. Larger rockets cut

slots in the body tube with the fins passing through the slot and glued to the

motor tube with fillets at the airframe/fin joint. Sunward instead supplies

card stock cutouts that are glued to the sides of the fins at the root edge and

these assemblies are then joined to the airframe tube creating a pre-assembled

fillet.

The fins are laser cut from 1/8-inch semi-hard A-grain balsa stock. They are still hanging on to the sheet by short spots left unburned and are carefully removed using a sharp hobby knife. The edges are lightly sanded to remove the burned material from the laser. At this time I cut out all of the cardboard parts too. I noticed while cutting that the quality of the printing and graphics lines vary markedly--some of the lines are quite bold while some are very thin. Also, the curved edges are very jaggy and the dashed fold lines are quite heavy which later made getting an accurate fold difficult. The fin is the first part assembled. A pair of tabs are glued to the sides at the root edge. Before bending the tabs, I scored along the bend line very lightly using a straight edge to ensure a nice straight and crisp fold. As stated, the fold line is very bold and my score line was run down the center of the line on both parts. These are then glued to the fins keeping the fold line flush with the root edge. While these tabs were drying I went on and assembled the tabs on the main and aft wings as well. There is a problem with all of the fin tabs: they are all too long. Not one fit the fin or wings properly and required a good deal of trimming to remove the overhanging parts. We aren't talking a little amount here, we're talking on the order of a half inch in some places. At first I thought that I had the wrong tabs but double checking proved that I am using the aft wing tabs where the aft wing tabs are called for. Same for the fins.

The body tube is

marked using a guide cut from the plans to locate the parts. The instructions

have the builder mark the top and bottom center lines, then slide the marking

guide up and down the tube when marking the fin locations. They also suggest

using a book for the straight edge. The doorjamb has been my handy marking

guide for a long time.

The body tube is

marked using a guide cut from the plans to locate the parts. The instructions

have the builder mark the top and bottom center lines, then slide the marking

guide up and down the tube when marking the fin locations. They also suggest

using a book for the straight edge. The doorjamb has been my handy marking

guide for a long time.

The fin tabs are now curled slightly with hobby knife handle to match the curve of the body tube and then the fin and tabs are glued down with the aft of the fin flush with the end of the tube. This is where I began to have some trouble. The first problem is that the line is blocked by the fin and tabs so it's truly troublesome to get the thing straight. I was able to line up one edge at both ends where the line is visible. Also, the plans warn not to get glue on the outside of the tabs but I found this very difficult since the glue naturally oozes out from under the tabs, and to get good contact, one naturally presses and holds the fin and tabs to the tube resulting in getting glue all over one's fingers and consequently all over everything you touch (including the outside of the tabs.) I used a tissue with a dot of water to attempt to clean up but without much success.

While that was drying, I read ahead in the instructions again and rolled the shroud to get it set for when I'll be ready for it. The edge was taped together and it was held with weights on the workbench to help fix the shape while the fin and wings were being glued.

The aft wings were glued on at this time, again having some trouble with alignment and glue but using care and time were placed correctly. I really like for my rockets, large and small, to fly straight!

The aft wings and fin were allowed to dry overnight, and the forward wings were glued on the following day. I made an error here that I found out too late. There are a long set of tabs and a short set of tabs for the main fins. The long set are for the main wing to shroud joint, and the short ones are for the main to body tube joint. I accidentally reversed these and had to cut a second set from scrap for the shroud to wing joint. And this after all of that double checking done earlier because the tabs are so much longer than the balsa parts!

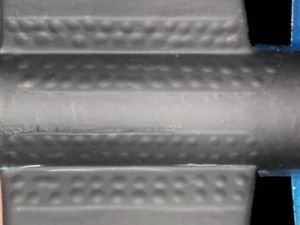

Next comes the

shroud. After the shape is set by curling and holding in position for a while,

the slots for the fins are cut. The shroud is then test fit and the

instructions indicate that the fin slots are trimmed to size. This is overly

optimistic since the holes indicated on the shroud are way too long. I was

careful to cut where indicated using a straight edge and a sharp knife so it

isn't due to my ham fisted cutting. We aren't talking a few millimeters here

either! The shroud is then glued to the top of the rocket using the top line

for alignment. When dry, the bottom is glued along the bottom line and tabs are

added to the wing joints. A strip of paper is added to the aft of the shroud.

The large gaps at the fin joints were fixed with scraps of paper. The plan at

this point is to make these appear as sheet metal so seams and gaps, etc., are

not a problem.

Next comes the

shroud. After the shape is set by curling and holding in position for a while,

the slots for the fins are cut. The shroud is then test fit and the

instructions indicate that the fin slots are trimmed to size. This is overly

optimistic since the holes indicated on the shroud are way too long. I was

careful to cut where indicated using a straight edge and a sharp knife so it

isn't due to my ham fisted cutting. We aren't talking a few millimeters here

either! The shroud is then glued to the top of the rocket using the top line

for alignment. When dry, the bottom is glued along the bottom line and tabs are

added to the wing joints. A strip of paper is added to the aft of the shroud.

The large gaps at the fin joints were fixed with scraps of paper. The plan at

this point is to make these appear as sheet metal so seams and gaps, etc., are

not a problem.

The motor mount and shock cord are now glued into the body tube. The provided launch lug is cut in two and the two halves are glued along the bottom line. The standard shock cord mount is OK and widely used but hard to replace later and in my experience causes the chute and shrouds to hang up in the body tube at ejection. I used the Quest solution for this: a Kevlar® cord attached to the top motor ring with the shock cord tied to this. I also added an ejection baffle just ahead of the motor mount. The baffle consists of a four inch length of BT-50 and a balsa disk. The tube has a few 1/4-inch holes in the sides, and the top disk has three 1/4-inch slots cut around the edge. The BT-50 is glued to the disk such that the slots are offset from the holes. The ejection charge fires up through the BT-50, exits through the holes in the tube, and up through the slots in the balsa disk. This action causes the charge to change direction and swirl around allowing the still burning particles time to burn out and the hot gasses a chance to mix with the cool air in baffle.

The instructions indicate that the fin and wing leading and trailing edges can now be sanded round. Normally, I would have done this step before gluing but wanted to see how tabs would work out first. As it turns out, this was a mistake--sand the fins before you glue yours down! I was able to get the edges sanded round, but it wasn't easy.

There was a year long pause in the constructing of this kit between the shroud installation and sanding of the fins. This was partly due to my reluctance to start on a sanding job that was almost certainly to be a pain, partly due to the flying season arriving, and partly due to other projects and a call to do some high power flying. This review was written largely as it happened, but in the meantime, the guys that I normally fly with found some of these kits and started bringing them to the launches. Most of them turned out pretty nice.

Finishing:

The seam lines in the plastic nose cone were sanded smooth and the entire nose

was sanded lightly. The lines were deep and required a good bit of work to get

smooth. The spirals in the tube were filled with Elmer's Fill 'n' Finish and

sanded. The fingerprints were also sanded off all the parts. The fins were

given four coats of AeroGloss sanding sealer with a light sanding in between

coats and a finish sanding with 400 grit paper. I considered attempting to fill

and smooth all of the tab seams but decided it would be too much work and, as

indicated earlier, I decided instead to make use of the tabs by making them

appear as sheet metal. The rocket was primed with white sandable primer and

sanded lightly with 400 grit paper. I used a syringe that I use to deliver

epoxy to close areas to create a line of fake rivets all around the tab edges.

It turns out that my faux rivet making skills need some work. The epoxy was

thin enough to pass through the syringe but took so long to set up that it

flattened out and ran together in places. Something other than epoxy (or at

least the type I was using) would make better rivets. Some research and testing

on this technique is needed.

The rocket was then painted with gloss blue paint and trimmed with black paint. I used aluminum paint for the canopy and had some trouble with the base color flaking away when the masking tape was removed--I was using the low-tack blue tape, too! The decals were applied at this point--these are a thin, self-adhesive type on a single sheet and cut out with scissors. Self sticking decals are improving as these went on without a lot of trouble and look OK as the substrate blends into the paint reasonably well. There are a very few decals and while they look OK they also appear very simple. I don't know about the Canadian Military, but the U. S. military plasters markings, warnings, and instructions seemingly everywhere and this very limited number of decals seems strange to me. The rocket was then coated lightly with a clear gloss coat.

Construction Rating: 4 out of 5

Flight:

First flown at our club launch in February 2004 on an Estes C6-3. The flight

was a sort of long arcing flight with some very strange oscillations starting

somewhere near apogee and continuing until ejection. The second flight was

quite weird and a lot lower on a B6-2. The ejection might have been a tad

early. I was messing around trying to get a good photo of the flight and didn't

fully appreciate the wobbling.

Flight Rating: 4 out of 5

Summary:

PROs:

- This is truly a builder's kit and believe it or not, is a fun kit to build. It isn't a simple three-fins-and-a-nose-cone rocket that one can slap together in an afternoon. Time and effort are required to produce a good product.

- The laser cut fins are terrific, and the design is very eye catching both on display and in flight.

- The instructions are clear and well illustrated and most problems I experienced where my own fault for missing something in the instructions.

- The motor hook is also very interesting but hasn't been well tested by me as yet.

- The shock cord has been getting good reviews on the flight line. This material is more in line with that used by another long standing manufacturer in times past and seems to be resistant to heat.

- The rewarding finished product makes up for the problems with the tabs and slots.

CONs:

- The tabs make the fins tricky. It's hard to get them lined up because of the nature of the tabs blocking the view. Also, the tabs could easily cause the fin to not make good contact with the body tube and the glue gets everywhere. I've never had so many fingerprints everywhere! It occurs to me that the fins should be glued to the airframe and then add the tabs.

- Rounding the fins after the rocket is constructed is a nuisance--it's a lot easier to do and to get even before they are attached to the airframe.

- Lastly, the problems with the tabs and slots not being the correct size are a pain. I know I keep whining about them, but these things combine to take a lot of the joy out of the building.

Overall Rating: 4 out of 5

Other Reviews

- Sunward Aerospace Phoenix By Bob Cox (July 9, 2007)

Brief: The Phoenix, like many other kits from Sunward Aerospace, is a conventional single-stage rocket with parachute recovery and is styled to look like a fighter jet. Construction: Parts list: 1 PNC56 Plastic Nose Cone with Canopy 1 18" BT56 Tube 1 Laser-cut balsa fin sheet 1 18" plastic parachute, clear and red 1 18mm motor mount kit 1 ...

- Sunward Aerospace Phoenix By Nick Esselman

Sunward Aerospace is a Canadian company with a unique line of model rockets, most of which fall under their RocketFighters design. They put together a quality package, including colorful front card, parachute printed with their name and thorough instructions. Each of the their kits use their own canopy-type nose cone as well. I chose the Sunward Phoenix due to its sleek design. I also believe ...

|

|

Flights

|

|

|

|

B.F.B (August 17, 2005)