| Manufacturer: | BSD High Power Rocketry  |

Brief:

Brief:

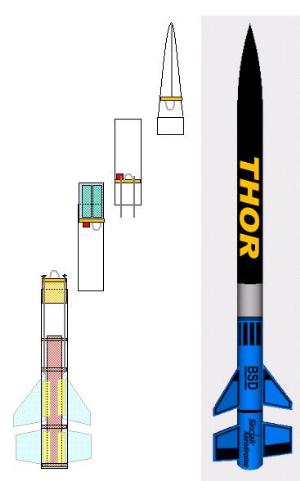

Kevlar®/Fiberglass body with Carbon Fibre reinforced fins mounted externally to

the motor mount. Giant leap electronics bay added for dual deployment. All

thread reinforcement of zipperless fin-can. Nosecone reinforced and thickened

with fiberglass. Internal nosecone all-thread and bulkhead added for recovery

harness attachment.

Modifications:

GENERAL: Well first let me say that I like Scott Binder's rockets as they are

always high in 'design character'. Scott always includes loads of decals and

the specs for the rockets are always well within the norm for design stability.

This usually gives you lots of options when deciding upon motors to use. I

decided on the Thor as it had a nice fin design and was perfect for a kit bash.

I also wanted a commercially recognizable 4" diameter rocket in which I

could put the largest 54mm motor I could get my hands on (in this case for the

UK an Aerotech K700). The idea is to lure your fellow rocketeers into thinking:

"Oh. here is a BSD Thor. I hear that it flies great on an I211W" and

then put in a K700 and hear the 'wooooooow' from the crowd when it blasts off

the pad. So with this in mind I needed to ensure that the rocket would be able

to withstand the fierce thrust of a K700. To this end I modified the stock BSD

THOR as follows:

a) Kevlar® and Fiberglass all body tubes using Giant Leap airframe sock and 4oz Fiberglass cloth. Vacuum bagging of layups using trusty foodsaver and West Systems epoxy.

b) Carbon fibre reinforcement of fin-can coupler (used 50/50 6oz woven fabric). Used 'balloon' method to reduce resin content after layup.

c) Carbon fibre reinforcement of fins with additional 6oz Unidirectional (vertical) S-glass cloth. Vacuum bagged using foodsaver. Note I pre-bevelled the fins using my Dremel prior to applying the layups of carbon fibre and fiberglass.

d) Slot fin-can airframe tube all the way down for insertion of external motor/fin assembly.

e) Used two 1/4" all threads to reinforce centering rings and attach to fin-can airframe tube coupler to distribute thrust and recovery stresses.

f) Used a Giant Leap electronics bay to connect airframe and payload bays and allow rocket to be rigged for dual deployment.

g) I increased the external width of the nosecone to match the increase in size of the airframe from the layups. It was also necessary to reinforce and lengthen the shoulder of the supplied ACE nosecone (I didn't want to change the look of the rocket just make is stronger so I stayed with the same nosecone and reinforced it).

h) A 4" coupler bulkhead was reduced using my Dremel and used along

with a 1/4" althread to create a recovery harness anchor inside the

nosecone.

h) A 4" coupler bulkhead was reduced using my Dremel and used along

with a 1/4" althread to create a recovery harness anchor inside the

nosecone.

i) Attach fins directly to motor mount with carbon fibre tape reinforcement to create a fin-can assembly with the all-threads and motor tube coupler attached.

j) Attach fin-can assembly to slotted airframe tube. Epoxy and carbon-fibre tape were used to reinforce the fillets and create a solid bond to the airframe. The fin-can coupler was also epoxied in place to finish the zipperless airframe/motor assembly.

Well....this all took some time to get through but the result has been a very strong airframe incorporating a zipperless design ready for dual deployment. All that remained was the finishing (I will describe this below).

Construction:

Kit comes stock with (3) body tubes (kraft), (2) coupler tubes (kraft), (3)

centering rings, elastic shock cord and Ace nosecone. Decals and motor

retention are also provided. The BSD Thor uses a 3 split-fin design with

through the wall attachment to a 54mm motor mount. The motor mount is 12"

long.

The packaging was as usual first rate for BSD rockets. No parts were broken with the exception of one fin decal which was missing (must have been an 'end of run'). Anyway a quick note to Scott Binder and a new fin decal was on its way via Deepsky Rocket Supplies.

The instructions where largely ignored since this was always going to be a kit bash. The kit did come with a fin-alignment guide and detailed instructions for anyone building this kit from stock. Since this rocket was NOT going to be a stock Thor I decided to change the look slightly to give it that 'custom' spec look. So instead of a white or yellow booster I used a light metallic blue and the gold leaf was replace with silver mylar. Finally I decided that instead of just Thor as a name I would call it THOR+ to hint that this was more than a stock built Thor. I have to say that if you are going to use Mylar or any thin film self sticking decals do NOT cover them with other decals as Mylar tends to breath with the rocket (shrink and expand) and if it is bound by other decals will create wrinkles (and not immediately but later --- very annoying).

Prior to painting I of course used some SuperFil (mostly on the booster) to

smooth out the rough spots. I also used 3 coats of UV SmoothPrime to cover the

weave of the fiberglass. The result was a pretty smooth finish (I could have

spent months but it still looks pretty good). After several coats of 'filler

primer' paint I glossed the airframe (blue for the booster and black for the

rest). Decals were applied later after Scott Binder kindly sent me some new

THOR+ decals (thanks Scott). I must admit to being proud of my creation. It

looks good and has that 'special edition' feel to it.

Prior to painting I of course used some SuperFil (mostly on the booster) to

smooth out the rough spots. I also used 3 coats of UV SmoothPrime to cover the

weave of the fiberglass. The result was a pretty smooth finish (I could have

spent months but it still looks pretty good). After several coats of 'filler

primer' paint I glossed the airframe (blue for the booster and black for the

rest). Decals were applied later after Scott Binder kindly sent me some new

THOR+ decals (thanks Scott). I must admit to being proud of my creation. It

looks good and has that 'special edition' feel to it.

Flight:

Well this rocket has only flown once so far on a J460T to give it a shakedown.

I used motor ejection (having drilled vent holes in the motor coupler bulkhead

to allow the gasses to pass into the airframe) and rigged the main chute into

the lower section of the rocket with the drogue (for weight mostly) in the top

payload section (with a connection to the nosecone bulkhead in the event of

pre-mature separation). The flight was perfect with a very slight weather

cocking due to its 2 caliber over stability and a 15mph wind. Even so it still

went very straight. Recovery was 1/4 mile down range where it landed on its

SkyAngle 44 parachute (very nice). The rocket didn't even suffer a paint

scratch.

Summary:

Pros: Very nice kit but since I didn't build it stock I can't say much else.

Cons: Well, I suppose the elastic shock cord is a minor point and the ACE

nosecone as well. The couplers are a bit thin for my liking but are probably

fine.

Other Reviews

- BSD High Power Rocketry Thor By Chuck Pierce

( Contributed - by Chuck Pierce - 04/01/03) Mark Saunders, of BSD High Power Rocketry, graciously donated a 4" Thor kit for a raffle prize, for the Huntsville Area Rocketry Association's (HARA) Rocket City Blastoff (RCBO), October 2002. I was the lucky winner of this kit, and as such, would like to reward Mark's generosity by posting this review to RMR. I approached Mark during ...

- BSD High Power Rocketry Thor By Allan Trau

(by Allan Trau - 07/01/02) Brief: Single stage, dual deployment capable, three split-fin design. Construction: The kit includes: 3 body tubes, 34" aft, 10" electronics payload, 24" forward 2 coupler tubes 3 plywood centering rings 3 aft 3/16" plywood fins 3 fore 3/16" plywood fins plastic nose cone 45" nylon chute 20' elastic ...

- BSD High Power Rocketry Thor By Allan Trau

When I purchased my BSD Thor, I knew I would also need to purchase new motor hardware. So I also purchased a 38mm set with a 38-240, 360 and 480 case. I also purchased a PML 54mm to 38mm adaptor to allow me to fly the 54mm-based Thor on my new hardware. So needless to say, this was a large outflow of money to venture into the largest rocket I have built. Is it the tallest I've built? No, the ...

|

|

Flights

|

|